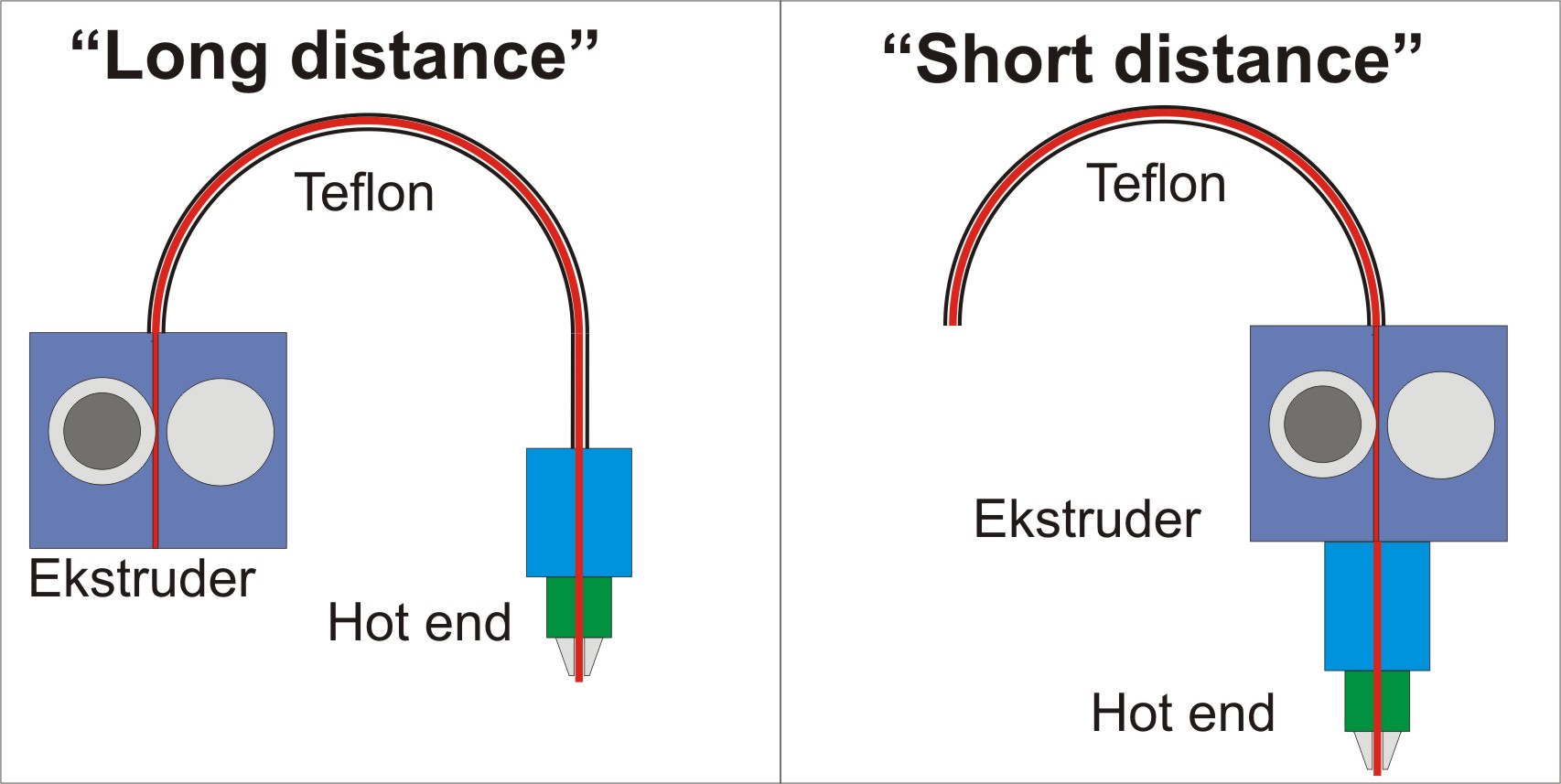

Kompendium wiedzy transport filamentu drukarki 3D

W związku z dość często padającymi przez klientów pytaniami dotyczący zgodności poszczególnych

elementów transportu filamentu w drukarkach 3D, chciałbym w zarysie wytłumaczyć jakie najczęściej elementy składowe oraz ich rodzaje składają się na w/w.

Read moreelementów transportu filamentu w drukarkach 3D, chciałbym w zarysie wytłumaczyć jakie najczęściej elementy składowe oraz ich rodzaje składają się na w/w.