Add products by adding codes

Brush Motor Construction - Everything you need to know about it

Brush motors, also called commutators, they have changed technology since their inception in the 19th century. My with its simple design and reliability have mastered many areas. They concern both the automotive industry and equipment for the home.

Understanding how they work and how they are built is important for engineers, technicians and even hobbyists. In this text you will learn more about their construction, operation, applications, as well as advantages and disadvantages.

Key Findings

- Brush motors is a key technology in the automotive industry, home appliances and power tools.

- They are characterized by simplicity of construction and low production costs, which makes them widely used.

- They are used in many industrial systems, where their reliability i performance are key.

- Brush motors are an important part of the development of electric drive technology.

- Understanding the design and operation of brush motors is essential for engineers, technicians and hobbyists interested in the field.

Introduction to Brush Motors

Electric motors are becoming popular and are used in many fields. These are m.in. industry and daily life. Brush motors, also called commutator motors, are very important.

They are very simple to build and cheap to produce. They were invented in the 19th century by many famous people. These include Ányos Jedlik, Michael Faraday or Thomas Edison.

Brush motors are divided into direct current motors (DC) and brushless (BLDC). Each type has its own special uses.

DC motors are valued for their simplicity and low price. Suitable for applications that need speed control. BLDC motors, on the market since the 1960s., are more efficient. They can work with electronic controllers, which gives you more options.

Both types of engines are very useful in many industries. They are used m.in. in automotive or automation. Each has its own strengths and weaknesses, which makes them useful in different situations.

In the following section we will look in more detail at the construction, operation and applications of brush motors. This will give us a better understanding of their importance in electric drives today.

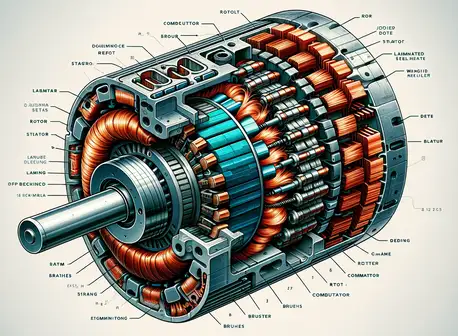

Components of a Brush Motor

Brush motors consist of many parts. These components, like the stator, rotor or commutator, together they create a movement that drives us. Each of them has an important role.

Stojan (Stator)

- The stator is the part of the engine that does not move. It contains the core and windings, that produce magnetism. The core is made of metal sheets, and copper wire is wound on it. Magnetic field of this element makes rotor spins.

Rotor

- Rotor is the part that is moved in the engine. It consists of a core, windings and commutator. On the rotor arm there is a certain number of turns of wire, e.g.T stands for the number of turns of wire. Wire thickness is usually not mentioned.

Brushes

- Brushes are used to transmit current to the rotor and are made of graphite or carbon. These materials provide protection against temperature and wear and tear. At the same time, they allow the rotor to be powered from the outside.

Commutator

- Commutator is the part on the rotor that changes direct current to alternating current. It consists of copper segments, separated by an insulator. Its task is to supply energy to the rotor in a commutator motor.

Housing and Shaft

- The housing protects the inside of the motor, and the shaft transmits the rotating rotor to another machine. It is important to match the dimensions of the shaft with the drive components. This is how we will ensure the smooth operation of the entire system.

Brush motors have always been valued for their simple operating principles. They are still used in modeling and can easily be converted to brushless. However, it costs more.

Operating Principle of the Brush Motor

Brush motors, also known as commutator motors, operate through electromagnetism. Produce rotational motion by bringing a magnetic field into contact with an electric current. In this process, a key role is played by commutator, which controls current flow in the rotor.

Magnetic Field Generation

- Electricity flowing through windings stator forms magnetic field. Windings are arranged so that the field is evenly distributed.

Current flow through the Rotor

- The supply current reaches the rotor through the brushes and commutator. This creates a separate magnetic field.

Interaction of Magnetic Fields

- Electromagnetic forces are the product of the interaction of the magnetic fields of the stator and rotor. They, in turn, cause rotor rotation and give the engine a rotary motion.

Switching the Direction of Current

- Rotary motion is possible thanks to a commutator that changes the direction of current flow. This maintains the balance of electromagnetic forces, ensuring stable movement of the motor.

A short sequence of electrical events creates the motor's rotary motion. Elements such as commutator and field interaction are key in this process. With them, brush motors can provide constant, uninterrupted motion.

Brush Motor

Electric motors, of which brush motors, are very popular today in various applications. They are considered more reliable than internal combustion engines. They also have better performance and are more efficient. Brush motors, or commutator motors, can be found in many areas of life and industry.

This type motors are built with current commutation brushes. Thanks to them, the direction of the current is changed, which makes it possible to generate rotary motion. They are fairly simple to build, which lowers costs and makes repairs easier.

Brush motors, despite their advantages, also have their disadvantages. They need to be serviced regularly, especially replacing worn out ones brushes, to last longer. They are also louder and vibrate more than other types of engines.

Their prices start from about 23 PLN and go up to more than 160 PLN, it depends mainly on the power and other technical parameters. For example, brush motor 400 6V 15000 RPM by is priced at $29.90, while the Brush Motor 600 6V 15000 RPM - PLN 39.90.

Despite the trend of increasing popularity of brushless, brush motors are still used in many fields. This is due to their simplicity and low cost. These engines are easy to repair and maintain.

They are characterized by low construction and operating costs. They can be easily repaired and rebuilt. They are ideal for harsh working conditions. Replacing toothbrushes is cheap and easy.

Brush Motor Applications

Brush motors are very popular due to their simplicity and reliability. They have found applications in various fields of industry and everyday life. Their ability to work in harsh conditions is very important.

Automotive Industry

In the automotive industry, they are used for starters and accessories like windshield wipers and pumps. They are inexpensive to maintain, which suits vehicle manufacturers very well.

Home appliances

- In household appliances, such as vacuum cleaners and washing machines, they also play an important role. They are simple to build and inexpensive, which manufacturers like

Power Tools

- In power tools such as drills, brush motors are popular. They are powerful and reliable. They perform well in harsh conditions and are low maintenance.

- They also find their place in electric toys and in the industry.

Brushless motors are gaining popularity due to better energy efficiency. However, brush motors continue to be important due to their simplicity, reliability and inexpensive price.

Advantages of Brush Motors

- Brush motors have many good points. They are easy to build and repair. This makes their production costs low.

- They are characterized by high power at switch-on. They are ideal where work needs to move quickly. You can also control their speed and rotational force, which is a big plus.

- There is another important advantage of these engines. They are very reliable even in difficult conditions. Work well even in high temperatures or humidity.

"Brush motors are a great choice for applications where key simple design, reliability and ease of use."

Disadvantages of Brush Motors

Brush motors, despite their many advantages, also have disadvantages. This should be taken into account when choosing a drive. It is necessary to have them regularly maintenance due to wear of brushes and commutator.

They also generate noise and vibrations, which can be a nuisance.

Their performance and energy efficiency is lower than in brushless motors. Speed limits rotational speed are due to the mechanical limitations of the brushes and commutator.

Limited Lifespan

- Limited lifespan brush motors are the result of wear and tear on the brushes and commutator. In comparison, brushless motors do not have these parts, so they last longer.

Noise and Vibration

- Noise and vibration during brush motor operation can interfere with household appliances or power tools. Brushless motors are quieter.

Less Efficiency and Effectiveness

- Brush motors are less powerful and less energy efficient than brushless motors. They consume more electricity, which increases operating costs.

Speed Limits

- Due to mechanical limitations, brush motors also have a speed limits rotating. Nevertheless, brushless motors can run faster.

In conclusion, brush motors have their disadvantages, such as the need for frequent maintenance and noise generation. Also their lifespan is shorter, and performance lower. That's why brushless motors work better in many situations.

Construction of the Electric Motor

At the heart of any electric motor are three important parts: the magnet or magnets, rotor and commutator. The rotor is composed of coils set by a difference in angles. This allows it to rotate smoothly. The commutator consists of plates interrupted by an insulator. Its task is to control the direction of current flow.

The stator is usually made of cast iron or aluminum. There are also engines without a table. Such are used in smaller devices. Brushes are made of graphite or copper coated with metals. Act as a rectifier. Recently, motors without brushes or commutator are becoming popular.

Electric motors are important to our lives. They are encountered in many devices, such as electric toothbrushes and hair dryers. Their work is described by the simple rule of three fingers. These devices convert electrical energy into mechanical work.

Principle of Electric Motors

The electric motor works by principle of interaction of magnetic fields. It consists of several basic parts: stator, rotor, main shaft and brushes. The motor usually has three stator coils, which affects its power output. You may also come across rotors with extra coils to get higher speed.

Inside the engine you will also find copper wire. Choosing thin wire gives us more room for coils. The simplest motors have two brushes, but today there are also brushless models.

Electric motors work on the principle of interactions of magnetic fields and flowing current. They can be divided into direct current and alternating current.

The former can be either foreign-induced or self-excited. Such that moths from the source are more versatile. AC motors can be synchronous, but are more often asynchronous. Today it is the most popular electric drive technology.

Commutator ones, on the other hand, have a special winding with a commutator where they move carbon brushes. Brushless motors give better control and use less power.

The engines work by rotor rotation. All phenomena occur due to magnetic fields and flowing current. They are an integral part of various industries. Their development has affected many processes in our daily lives.

"An electric motor converts electrical energy into mechanical energy. Its invention has influenced today's technology, making everyday life easier."

Difference between Brush Motors and Brushless Motors

Electric motors are important in every device we know, from toys to cars. They are divided into two types: with and without brushes. Each has its own strengths and impact on the operation of the machine.

Brush motors use brushes and commutators. They are less efficient than brushless ones, which operate from 85 to 90% of their power. Motors with mechanical brushes must be serviced often and wear out faster.

Brushless motors are more durable and don't need as much attention. They are also quieter and have more torque than those with mechanical brushes.

Depending on your needs, choose between a motor with or without brushes. Engines with manifolds are better where you need to control speed, like in modeling. Brushless motors are better suited for high-speed models, robots or electronic devices.

Let's add up. Brush motors are cheaper and control speed well. Brushless, on the other hand, are more efficient, more durable, quieter and have better torque. The choice of engine depends on what we need.

| Feature | Brush Motors | Brushless Motors |

|---|---|---|

| Efficiency | ~75% | 85-90% |

| Lifespan | Limited (require maintenance) | Longer (no wearing parts) |

| Noise level | Higher | Lower |

| Torque | Lower | Higher |

| Price | Lower | Higher |

| Applications | Off-road vehicles, tools | RC models, electronic devices, robots |

Brushless motors are used in a wide range of fields, from consumer electronics to industry, thanks to their advantages in durability, efficiency and speed control. Their compact design and high performance make them the preferred choice for many modern applications, such as robots, wearable devices and micromachines.

Innovations in Electric Motor Technology

Electric motor technology is in constant development. Engineers are looking for new ways to improve these devices. They want them to be more efficient, more durable and more effective. More and more electric-powered vehicles will be on the road in India. By 2030. their number may increase to 70%. Ring motors are now a popular choice in electric vehicles. They have great performance and save energy. Elimen Group company together with FLASH of Pune is developing the technology of these engines.

Ring motors are not only efficient, but also save energy. With them, the vehicle range can be extended. Another advantage of these engines is their quiet operation and easy integration into vehicle systems. That's why manufacturers are eager to use them in their vehicles.

These motors offer a lot of advantages: higher efficiency, energy savings and quiet operation. They are also easy to integrate with other vehicle systems. This makes them a good choice for the future in electric motoring. They may be slightly more expensive than classic engines, but in the long run we save on energy and operation. Depending on the model, ring motors vary in power and torque. This gives a choice suitable for different market needs.

In Poland, the most commonly used voltages are 230V and 400V. Each is dedicated to different types of installations. Small appliances, like fans, need motors with a few kilowatts of power. On the other hand, for industrial machines, motors with more power are necessary.

There are different types of loads for electric motors in industry. Among the most common are m.in. variable power and constant torque. At the moment, brushless DC and squirrel cage AC motors are most commonly used in industry. Each type of motor is adapted to different applications.

When choosing a motor, you need to consider whether you need a constant speed or position. A lot of industrial applications require different solutions. Machines such as cranes are used for such applications, as well as pumps or cylinders.

You can increase the efficiency of AC motors by combining them with inverters. For precise control of torque and position, sometimes servomotors or stepper motors are needed. These solutions are a big help to the industry.

| Type of Load | Engine Type | Examples of Applications |

|---|---|---|

| Variable power and constant torque | AC squirrel cage motors, ring motors | Conveyors, cranes |

| Variable torque and constant power | DC brushless motors, servo motors | Pumps, paper winding machines |

| Variable power and variable torque | AC squirrel cage motors, ring motors | Fans, centrifugal pumps, mixers |

| Position and torque control | Servomotors, stepper motors | Linear actuators |

When choosing an engine, it is important to consider many factors. You have to think about moments, friction, efficiency. There are many ways to control the engine. Each has its uses, such as soft starts or overload protection systems.

"The development of electric motor technology is key. Thanks to them, the energy and automotive industries are radically changing. These are important innovations for the new technology industry."

FAQ

What are brush motors and how they work?

Brush motors is a special group of motors, also known as commutator motors. They use magnets and electricity to move. Their function is to transmit electricity to the entire engine, which causes it to rotate.

What are the main components of the brush motor design?

They consist of several important parts. It's stator, which is stationary and made of magnets. We also have there rotor, which rotates and drives the whole.

Brushes are used to transmit current to the rotor. Commutator changes the type of current. Finally, motor housing and shaft surround and protect the interior.

How the brush motor works?

When we power a motor, the current creates a magnetic field in the stator. Brushes transmit electricity to rotor. This circulates current, creating a magnetic field around the rotor. This field catches on the stator field and drives the rotor to rotate.

Commutator changes the direction of the current so that the rotor can spin continuously. Thanks to this phenomenon, the engine can work.

What are the main applications of brush motors?

Brush motors are widely used in various areas. In automotive, they work in starters and accessories. In household appliances such as vacuum cleaners and washing machines. They also provide power to power tools, electric toys and industrial systems.

What are the advantages of brush motors?

These engines have many pluses. Their construction is simple, which facilitates production and repairs. They are cheaper in production. They have high starting power.

Easily control speed and torque. They are also reliable in harsh conditions such as high temperature or humidity.

What are the disadvantages of brush motors?

But they also have downsides. They need to be service frequently. They are less durable than brushless motors. They create more noise and vibration.

Their efficiency is lower. They also have restrictions on speed.

What is the difference between brush and brushless motors?

Brushless motors differ from the brush ones by the lack of parts that wear out. As a result, they are usable for longer, do not require as much service and are more reliable i effective.

What innovations are taking place in electric motor technology?

Engine developers care about continuous development. They are working on new materials and electronics to improve engines for performance and durability. They want to create products that better meet modern requirements.

Application

Electric motors, such as brush motors, are irreplaceable in the modern world. They are used in smartphones, watches, or massagers. They are simple to build and inexpensive. Their long-lasting and quiet operation are highly regarded.

Although they require frequent care and have limited speed, they are still popular. Their simplicity and reliability prevail. Scientists are working to improve these engines. They want to increase their efficiency and durability as a response to growing needs. Modern magnetic materials and optimized designs are used.

To summarize, electric motors, including brushes, are key to technology. With better technology, their role in everyday life and industry will grow.