Add products by adding codes

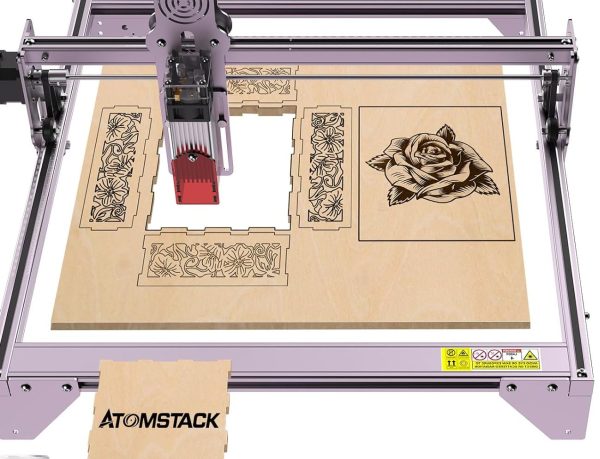

There is often a misconception that any plywood is suitable for laser cutting. Nothing could be further from the truth. Choosing the right material is key to achieving precise and aesthetically pleasing results. In this article, we will take a closer look at this issue to help you make the best choice. We will learn about the different types of plywood available on the market for laser cutting. Each of them has its own unique properties that can affect the final result. We will discuss both the advantages and disadvantages of these materials to help you decide. We will pay special attention to birch, pine and poplar plywood, which are often chosen for laser cutting. We will compare them in terms of various factors, such as strength, aesthetics or ease of processing. We will also share practical tips for cutting plywood with a laser. You will learn what techniques for maintaining plywood will ensure its longevity and maintain the best quality. Our goal is to provide you with a comprehensive knowledge of laser cutting plywood. We want you to be able to make informed decisions that will bring you satisfaction with your work. We invite you to read.

1. Choosing the right plywood for laser cutting

When choosing plywood for laser cutting, it is worth paying attention to several key factors. Plywood thickness has a direct impact on cutting efficiency. Plywood that is too thick can be difficult to cut, while plywood that is too thin can burn during the process. The ideal thickness of plywood for laser cutting is usually between 3 and 5 mm.

Type of wood, from which the plywood is made also matters. Some types of wood, such as pine or birch, are easier to cut with a laser, while others, such as oak or walnut, can be more difficult. It is important to choose plywood made of wood that responds well to laser cutting. Here are some wood species ideal for laser cutting:

- Birch: It is one of the most popular woods for laser cutting due to its uniform structure and ease of cutting.

- Pine: Pine is also easy to cut with a laser, but may require a bit more cleaning after cutting due to the resin.

- Poplar: Poplar is lightweight and easy to cut, making it an ideal choice for those new to laser work.

Finally, quality of the plywood is crucial. Low-quality plywood may contain air bubbles or bumps that can make laser cutting difficult. Therefore, it is always worth investing in high-quality plywood, even if it is slightly more expensive. Remember that better quality plywood translates into better cutting results.

2. Different types of plywood for laser cutting

When selecting plywood for laser cutting, it is important to understand that not all types of plywood are suitable for this process. Birch plywood is one of the most popular choices because of its smooth surface and uniform texture, which ensures clean and precise cuts. Other good options are poplar plywood i hardwood plywood, which are also easy to cut and offer excellent results.

When selecting plywood for laser cutting, it's a good idea to create a checklist to make sure the material you choose meets all the requirements. The checklist should include such points as the type of wood, the thickness of the plywood, the uniformity and smoothness of the surface, and the absence of knots or other defects that may affect the quality of the cut. Remember that low-quality plywood can lead to uneven cuts and potentially damage the laser.

3. What are the advantages and disadvantages of laser cutting plywood?

Laser cutting plywood has many advantages that attract both professionals and amateurs. High precision cutting this is one of the most important advantages for creating intricate designs and details. In addition, plywood is a relatively inexpensive material, making it an attractive choice for many projects. Nevertheless, laser-cut plywood also has its drawbacks. First of all, can emit harmful fumes during cutting, which requires adequate ventilation of the room. In addition, plywood can be difficult to cut for thick plates, which may require a more powerful laser.

- High precision cutting - allows the creation of complex patterns and details.

- Material relatively cheap - makes it an attractive choice for many projects.

- May emit harmful fumes - requires adequate ventilation of the room.

- Difficult to cut for thick panels - may require a more powerful laser.

4. Comparison of birch, pine and poplar plywood for laser cutting

When choosing the right type of plywood for laser cutting, it is important to understand the differences between birch, pine and poplar plywood. Birch plywood is known for its durability and precision cutting, making it an ideal choice for complex projects. On the other hand, pine plywood is softer and more flexible, which can be beneficial for projects that require some flexibility. While poplar plywood is lightweight and easy to cut, making it perfect for quick projects.

- Birch plywood: Features high strength and precise cutting, ideal for complex projects.

- Pine plywood: It is soft and flexible, which can be beneficial for projects that require some flexibility.

- Poplar plywood: It is lightweight and easy to cut, making it perfect for quick projects.

5. Practical tips for cutting plywood with a laser

For professionals and amateurs alike, cutting plywood with a laser can be a task that requires precision and skill. Choosing the right type of plywood is key to achieving optimal results. Below is a checklist to help you in this process:

- Plywood type: Not all plywood is suitable for laser cutting. Hard plywoods, such as oak or maple, can be more difficult to cut than soft plywoods, such as pine or poplar.

- Plywood thickness: Thickness of plywood affects the time and power required for cutting. Thicker plywood requires more energy and time.

- Laser settings: Different lasers have different settings that can affect cutting quality. Always check the laser manual before cutting.

- Safety: Laser cutting can be dangerous if not done properly. Always wear proper safety glasses and follow safety rules.

Remember that practice makes perfect. The more experience you gain, the easier it will be to achieve the perfect cut.

6. The best techniques for keeping plywood for laser cutting

Keeping plywood in perfect condition is key to achieving precise and clean laser cuts. Regular cleaning is one of the most important aspects of plywood maintenance. It is recommended that the plywood surface be thoroughly cleaned after each use to remove any residual dust and dirt that could affect the quality of cutting. However, excessive cleaning can lead to damage to the plywood surface, which is one of the main drawbacks of this technique.

Plywood storage under proper conditions is another key element in keeping it in good condition. Plywood should be stored in a dry and cool place, away from direct sunlight. This prevents it from cracking and distorting, which can adversely affect the quality of laser cutting. The disadvantage of this technique is that it requires adequate storage space, which can be problematic for some users.

Finally, regularly check and replace the laser is essential for keeping the plywood in perfect condition. The laser should be checked at least once a month to make sure it is working properly. In case of any problems, the laser should be replaced immediately to prevent damage to the plywood. The downside of this technique is that it requires regular maintenance and potential replacement of parts, which can be costly.

Frequently Asked Questions

Is laser cutting safe for plywood?

Laser cutting is safe for plywood, provided it is carried out by an experienced operator and proper safety measures are used. The laser is a very precise tool that minimizes the risk of damaging the material.Can I use any plywood for laser cutting?

Not all types of plywood are suitable for laser cutting. It is important to choose plywood that is smooth and even to ensure precise cutting. Birch, pine and poplar plywood are often used for laser cutting.What are typical applications for laser cut plywood?

Laser-cut plywood is often used in various craft projects, such as models, ornaments, signs and more. Thanks to precision laser cutting, plywood is ideal for creating intricate designs and details.Is laser cutting expensive?

The cost of laser cutting depends on many factors, such as the type of plywood, the size of the project and the time it takes to complete it. Nonetheless, laser cutting is often more economical than traditional cutting methods, especially for mass production.Is laser cutting environmentally friendly?

Laser cutting is considered environmentally friendly because it minimizes waste by cutting precisely. In addition, some lasers are powered by electricity, which is more environmentally friendly than traditional cutting methods.