Add products by adding codes

Strain gauges - transducers

( quantity of products: 8 )Strain gauges - precision force transducers

Strain gauges, also known as strain gauge sensors, are essential for accurately measuring weight or force. They are used both in simple structures, such as scales, and in more complex industrial automation systems. Strain gauge mat is just one of many components available in our offer.

The assortment of the ABC-RC store includes strain gauges with different characteristics, tailored to the needs of both amateurs and specialists in the field of automation. For detailed information about each product, please refer to its description. Strain gauge beam is another element that may prove essential to your project.

Introduction to strain gauging - force transducers

Strain gauges, or force transducers, are the devices needed to accurately measure force or weight. They are used in a variety of fields, from simple structures like scales to complex industrial automation systems. We offer various types of strain gauges, including strain gauge mat i strain gauge beam, which are essential elements of many projects.

Application of strain gauges

Strain gauges, also known as strain gauge sensors or strain gauge transducers, are widely used. They are used in industry, medicine, construction and even in sports. They can be found in scales, force measurement systems, material tension measuring devices or vibration and deformation control systems.

Division of strain gauges

Strain gauges are divided into different types, depending on their application and design. The most important of these are resistance strain gauges, which measure the change in resistance under strain, capacitance strain gauges which measure the change in capacitance under strain, and piezoelectric strain gauges, that use the piezoelectric effect to measure force or acceleration.

Selection of strain gauges

Choosing the right strain gauge depends on many factors. First of all, it is necessary to pay attention to the measurement range, accuracy, as well as the operating conditions of the transmitter, such as temperature, humidity or mechanical load. Our offer includes strain gauges with different parameters, so everyone, both amateur and professional, will find the right product with us.

Advantages of using strain gauges

The use of strain gauges brings many benefits. First of all, with them you can make very precise measurements of force, pressure or acceleration. In addition, the strain gauges are extremely durable and resistant to harsh working conditions. This makes them indispensable in many areas of industry.

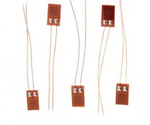

Construction of strain gauges

The construction of a strain gauge depends on its type. The basic element of any strain gauge is sensing element, which responds to changes in material tension. In resistive strain gauges, it is a wire or foil made of a material with a high resistance variation, in capacitive strain gauges it is a capacitor, and in piezoelectric strain gauges it is a piezoelectric crystal.

Take a look at our range of strain gauges. We are confident that everyone, regardless of their needs, will find the right product with us.