Add products by adding codes

What kind of plywood for laser engraving and cutting

Have you ever wondered which plywood is best for laser engraving and cutting? Do you always choose the same one, regardless of the project, or do you experiment with different types to see which gives the best results? If so, then this article is for you.

Welcome to the world of plywood, where not everything is as it seems. Did you know that not all plywood is suitable for laser engraving? What if we told you that choosing the right plywood can significantly affect the quality of your work?

In this article we will take a closer look at the different types of plywood available on the market, their properties and applications in laser engraving and cutting. We will compare them to help you decide which is best for your needs.

We will also suggest what to pay attention to when choosing plywood for laser engraving, what features it should have and how to take care of it after engraving and cutting.

Finally, we will share with you practical tips and the most common mistakes made when engraving and cutting plywood with a laser, so that you can avoid the pitfalls and enjoy perfect results.

Are you ready for this journey into the world of plywood? If so, buckle up and get ready for a fascinating read that is sure to illuminate more than a few issues related to laser engraving and cutting of plywood.

Have you ever wondered which plywood is best for laser engraving and cutting? Do you always choose the same one, regardless of the project, or do you experiment with different types to see which gives the best results? If so, then this article is for you.

Welcome to the world of plywood, where not everything is as it seems. Did you know that not all plywood is suitable for laser engraving? What if we told you that choosing the right plywood can significantly affect the quality of your work?

In this article we will take a closer look at the different types of plywood available on the market, their properties and applications in laser engraving and cutting. We will compare them to help you decide which is best for your needs.

We will also suggest what to pay attention to when choosing plywood for laser engraving, what features it should have and how to take care of it after engraving and cutting.

Finally, we will share with you practical tips and the most common mistakes made when engraving and cutting plywood with a laser, so that you can avoid the pitfalls and enjoy perfect results.

Are you ready for this journey into the world of plywood? If so, buckle up and get ready for a fascinating read that is sure to illuminate more than a few issues related to laser engraving and cutting of plywood. 1. Choosing the right plywood for laser engraving

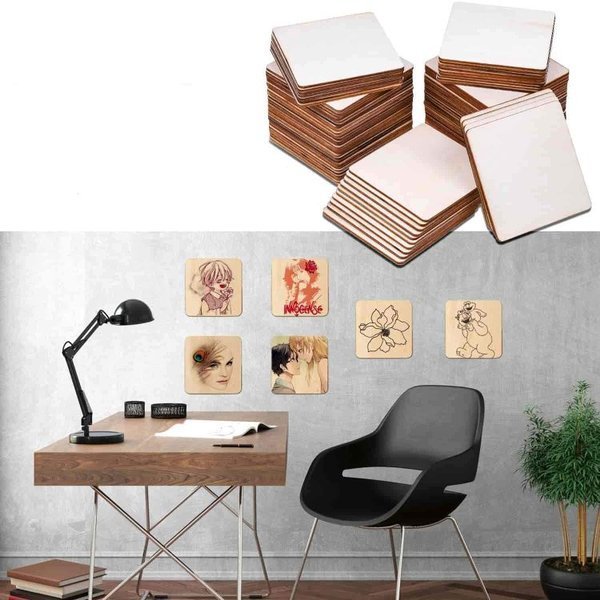

Choosing the right plywood for laser engraving is key to achieving optimal results. Birch plywood is often chosen for its uniform structure and ease of engraving. Its smooth surface ensures clean and precise cuts, which is especially important for intricate patterns and details.

When choosing plywood, it is worth paying attention to its thickness. The thickness of the plywood affects the depth of engraving and the time and power required to cut the material. Plywood that is too thick may require more laser power and longer cutting time, which can lead to burned edges. On the other hand, plywood that is too thin can be cut too deep or even burned.

Tip: Before starting engraving, it's a good idea to run a test on a small piece of plywood to determine the optimal laser settings. Keep in mind that different types of plywood may require different settings, so it's always a good idea to run tests before starting on a new material.

2. Different types of plywood for laser cutting

Birch plywood is one of the most popular materials for laser engraving and cutting. Thanks to its smoothness and uniformity, it provides precise and clean cuts. In addition, it is readily available and relatively inexpensive, making it an ideal choice for many projects.

- Hardwood plywood: This plywood is made of hardwood such as oak or maple. It is a good choice for projects that require higher strength and durability.

- Coniferous plywood: This plywood is made of softwood, such as pine or spruce. This is a cheaper option, but may not be as durable as hardwood plywood.

- Marine plywood: This plywood is specially designed for use in wet conditions. It is resistant to mold and rot, making it ideal for use outdoors or in areas where humidity is high.

When choosing plywood for laser cutting, it is also important to pay attention to its thickness. Thicker plywood may be more difficult to cut, but provides greater stability and strength. On the other hand, thin plywood is easier to cut, but may be less stable. The choice of the appropriate thickness of plywood depends on the specifics of a given project.

3. What features should plywood have for laser engraving?

When selecting plywood for laser engraving, it is crucial to pay attention to its density i homogeneity. High-density plywood with a uniform structure will ensure precise and clean cuts, which is essential for optimal results. On the other hand, low-density plywood can lead to uneven cuts and potential damage to the laser.

Plywood thickness is another important aspect to consider. Plywood that is too thick can be difficult to cut, which can lead to imprecise cuts and increased energy consumption. On the other hand, plywood that is too thin can be easily damaged during the engraving process. The optimum thickness of plywood depends on the specifics of the project and the power of the laser.

Finally, it is worth noting the surface quality of the plywood. Plywood with a smooth and uniform surface will provide better engraving results, as the laser will be able to penetrate the material evenly. However, plywood with a rough surface can lead to uneven engraving and potential damage to the laser.

4. Laser cutting plywood comparison: Which is best?

When analyzing different types of plywood for their suitability for laser cutting, birch plywood, poplar plywood or mdf cannot be overlooked. Each of them has its own unique properties that can affect the end result. Birch plywood, due to its hardness and density, is often chosen for precision work. Poplar plywood, on the other hand, being slightly softer, may be ideal for cutting with a less powerful laser. Plywood mdf, thanks to its homogeneity, is perfect for engraving. Choosing the right plywood depends on many factors, such as the type of laser, the precision of the cut or the expected end result. All this means that there is no clear answer to the question of which plywood is best - it all depends on your specific needs and expectations.

5. Practical tips for laser engraving and cutting plywood

Knowing the right techniques and tools is key to effective laser engraving and cutting of plywood. Using the right laser power is one of the most important aspects that can significantly affect the quality of the final product. Here are some practical tips that can help in this process:

- Use a laser with the right power: The laser power should be adapted to the thickness and type of plywood. Too much power may burn the material, while too little may not cut it completely.

- Choose the right plywood: Not all plywood is suitable for laser engraving and cutting. Birch and poplar plywood are the most common choices due to their uniform structure and low resin content.

- Determine the right cutting speed: Cutting speed should be adapted to the laser power and type of plywood. Cutting too fast can lead to uneven edges, while cutting too slow can burn the plywood.

6. Are all plywoods suitable for laser engraving?

When working with a laser, not all plywood will produce the expected results. Birch plywood is often chosen for its smoothness and uniformity, which translates into clean and precise cuts. However, this is not the only type of plywood that can be used. Much depends on the specifics of the project and the expected end results.

For example, poplar plywood is lightweight and flexible, which can be an advantage in some projects. However, its softness can also lead to slightly less precise cuts. On the other hand, plywood made of hardwoods such as oak or walnut can provide exceptional durability and strength, but cutting it with a laser can be more difficult and require more laser power.

It is important to remember that regardless of the type of plywood, the quality of the material is crucial. Low-quality plywood may contain air bubbles or bumps that can affect laser cutting precision. That's why it's always a good idea to invest in high-quality plywood to get the best possible results.

7. How to take care of plywood after engraving and laser cutting?

When working with plywood, especially after processes such as engraving or laser cutting, proper maintenance is key. Ensure that the surface is always clean and dry. Avoid leaving plywood in a humid environment, as this can lead to its destruction. Regular cleaning of plywood will keep it in excellent condition for a long time.

In the case of plywood that has been engraved or laser cut, it is recommended to use specialized maintenance products. These products will not only help keep the plywood in good condition, but also protect it from possible damage. Remember to always follow the manufacturer's instructions when using these products.

In conclusion, proper care of plywood after engraving and laser cutting is extremely important. With regular cleaning and the use of appropriate preservatives, plywood will be able to serve for a long time, maintaining its aesthetic i functional properties. Remember that each plywood requires a customized approach, so always pay attention to the specifications of a particular product.

8. The most common mistakes made when engraving and cutting plywood with a laser

When working with a laser, it is important to pay attention to safety i quality performances. One of the most common mistakes is setting the laser parameters incorrectly. Too high a power can lead to plywood burning, and too low a power can lead to insufficient cutting or engraving. That's why it's always a good idea to run tests on small samples of material before starting the actual work.

Choosing the wrong plywood is another common mistake. Not all types of plywood are suitable for laser cutting and engraving. For example, birch plywood is too hard and can lead to uneven cutting. Pine plywood, on the other hand, is too soft and can burn easily. The best choice is medium hardness plywood, such as poplar plywood.

Finally, it is worth remembering that lack of regular maintenance laser cutting and engraving equipment can lead to its damage and reduce the quality of work. That's why you should always keep your laser clean, replace its parts regularly and perform routine checks. Remember that even the most expensive and state-of-the-art device will not work properly if it is not properly maintained.

Frequently Asked Questions

- Laser engraving is safe for plywood, provided it is done correctly. Note, however, that this process generates a lot of heat, which can burn the plywood if not properly controlled.

- Yes, the thickness of the plywood has a significant impact on the laser engraving process. Plywood that is too thick may require more laser power and longer engraving time, while plywood that is too thin may be damaged by the laser.

- No, not all lasers are suitable for plywood engraving. The best results can be obtained with a CO2 laser, which is specially designed to work with wood and other organic materials.

- When engraving plywood with a laser, various problems can occur, such as burning of the plywood, uneven engraving or damage to the laser. Therefore, it is important to always monitor the engraving process and adjust the laser settings accordingly.

- Laser engraving is very durable and requires no special maintenance. However, plywood, like other wood materials, may require regular maintenance to maintain its appearance and durability.